gas analyzer in cement plant|The Key Role and Application of Gas Analyzers in Cement Industr : Chinese Continuous gas analyzer system is the perfect fitting solution for emission . Resultado da O tradutor público, também conhecido como tradutor juramentado, é uma pessoa habilitada em um ou mais idiomas estrangeiros, além do .

{plog:ftitle_list}

Exame toxicológico em São Paulo, melhor preço, resultado r.

The ACX analyzer system is tailored to the different cement applications. It ensures effective monitoring on the primary and secondary combustion, validates the clinker quality, minimizes the fuel costs through optimized combustion control and support a safe operation.Complete analyzer system. — With gas sampling, sample conditioning and gas .Continuous gas analyzer system is the perfect fitting solution for emission .

Complete analyzer system. — With gas sampling, sample conditioning and gas analyzer — Incl. system control and selfmonitoring — In sheet steel or glassfiber cabinet or on mounting plate .

The Key Role and Application of Gas Analyzers in Cement Industr

Gas analyzer systems at a glance With 35 years of experience and more than 600 kilns systems supplied worldwide, ABB is the market leader in cement plants providing state-of-the-art gas analyzers. ProKiln is the system designed for the sampling of hot cement flue gas at kiln gas exit. In presence of hard encrustations, the ProKiln allows the opera- Cement is an indispensable material in the construction industry, and the gases emitted during cement production pose a potential threat to the environment and human health. In this blog, the application of gas analyzers .Optimise Your Cement Plant with Digital; Supplementary Cementitious Materials; Research and Development. . Since its launch in 2003, the KilnLoq gas analyser system has become the preferred probe system for the cement . The pyro-processing system, which is the heart of the cement plant, requires a comprehensive set of instruments. These include temperature and pressure sensors for the preheater and the kiln, gas analyzers to monitor the composition of the kiln gas, and mass flow meters to measure the flow of materials through the system.

Systems based on the hot-wet measurement cope well with aggressive gas mixtures at the extreme kiln inlet conditions of cement plants. The basic idea behind the hot sampling technology is rather simple: keep all parts in contact with the gas sample well above the acid and water dew points to avoid any condensation and therefore any corrosion or .The CEMTEC ® gas sampling probe system was developed for continuous analysis of flue gas in cement plant rotary kiln inlets and other extremely dusty, . In addition to the InSitu sensors for oxygen and CO e analysis, extractive analyzers are supplied with dust free flue gas for measurement of e.g. SO 2, NO x or CO 2.

ABB provides analyzers for cement industry: continuous gas analyzer systems, emission monitoring, bulk material online measurements, and more. Offerings; . No other supplier has installed more gas analyzers on cement plants. More .Cement manufacturing requires rigor and precision to obtain products ofexcellent quality that comply with environmental standards.Controlling the manufacturing process, with reliable pressure, flow and temperature measurement instruments, helps to increase yield while extending plant life. The analysers gas monitoring system also helps to improve process control, while .

Some ABB devices, such as the Uras26 Infrared gas analyser have two measurement channels which can be used for simultaneous carbon monoxide (CO) and CO 2 measurement. That is an ideal solution for monitoring the catalytic conversion of CO to CO 2 which is increasingly being used on cement plants to mitigate CO emissions.Industry: Cement Product: Gas Analyzers APPLICATION NOTE Process Analyzers for Stable Long-Term Measurement of High-temperature, Dust-laden Gases . NOTE: 1 to 5 represent the measuring points in the summarized process overview for a Cement Plant. (*1) Water-washing/cooling probe is recommended, when sample gas temperature ≥ 800°C .

High-temperature, dust-laden environments require a robust gas analysis solution that delivers pinpoint accuracy. Anything less than maximum reliability is a waste of your time. We understand. We select the best available technology to create a gas analysis system that works for your process, with expertise built in.Whether for gas analysis in chemistry or for rotary kiln monitoring in cement works, whether for flue gas monitoring in waste incineration plants or in power plants – choose from a complete portfolio of measuring instruments for extractive continuous process gas analytics. . Select and order. Whether for gas analysis in chemistry or for .If you are working in the cement manufacturing industry, you need the right continuous emission monitoring system to perform your job safely, day to day. At MRU Instruments you can find the perfect gas analyzer for your job to detect many different gas components. If you are looking for an emission analyzer, combustion analyzer, or other gas analyzer, MRU Instruments has the .

Whether for chemical gas analysis, rotary kiln monitoring in cement manufacturing or for flue gas monitoring in waste incineration plants or power plants – Siemens offers a complete portfolio of measuring instruments for extractive continuous process gas analytics. Download Brochure.

It draws the sampled gas into the analyzer cell, eliminating the need for a mechanical pump and associated maintenance. As a beneficial side effect, the . cement plants can exhibit variability in emissions. This particular cement plant has two in-line raw mills.European cement plant responsible for instrumentation and analytical equipment. “No-one wants to risk a plant shut down,” he added. “Blockages occur more since the introduction of alternative fuels. Even the best probes tend to block today. The mechanical plunger system helps to unblock the probe and enables the analyser people to deliver,Optima AO2000 Series Continuous Gas Analyzers” data sheet. Another range of application of the analyzer systems is the con-tinuous detection of the gas concentration in cement plants during the primary combustion in rotary kilns and during the secondary combustion at the gas outlet of the calciner. In addi-

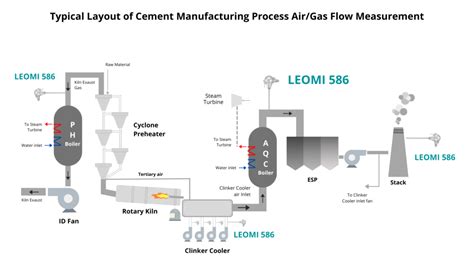

Advancement in Air & Process Gas Flow Monitoring in Cement Plants for Process Optimization . Cement Industry is one of the crucial core sectors for the development of construction and infrastructure with currently approx. 4.4 billion Tonnes of cement was produced in the world in the year 2021. The largest cement producer is China with more than .Series Continuous gas analyzers data sheet. Cement applications Another range of application of the analyzer systems is the con-tinuous detection of the gas concentration in cement plants dur-ing the primary combustion in rotary kilns and during the sec-ondary combustion at the gas outlet of the calciner. In addition, It is particularly useful for monitoring emissions and processing gases in cement plants. FTIR analyzers can detect a wide range of gases, including CO2, SO2, NOx, and VOCs. . Analytics is your trusted partner in providing state-of-the-art gas analysis systems tailored to the specific needs of cement plants. Our expertise in gas analysis . The gas analyser system is mounted in a shelter at a distance of approximately 10 m. Maintenance intervals. . Hot/wet gas sampling and analysis is an ideal solution for gas measurement at the kiln inlet of cement plants. Automatic cleaning of the sampling probe with back flushing of the filter probe, aided by a shock blow for complete removal .

CEMTEC _ Solutions for Gas Analysis in Cement Plants - Free download as PDF File (.pdf), Text File (.txt) or read online for free.

Siemens in-situ tunable diode laser analyzers are designed to measure components of interest from rotary klin monitoring in cement procesess to flue gas monitoring in waste incineration and power plants. Choose from a complete portfolio of instruments for measurements directly in the stack, duct or process stream without any sample handling or .

After the test run on the long distance. The final commissioning of the in-situ gas analyzer at HeidelbergCement plant Geseke took place in March 2019 (fig. 3). During the 12-month testing period (March 2019 – March 2020), SICK and the cement plant proved that in this application the GM32 has to be checked regularly only every 9 to 12 months.The Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing . ultimately to exhaust gas temperature. In cement plants increased airflow through the cooler reduces secondary air temperature, and therefore, the flame temperature, thus requiring even more fuel to heat the charge to the required .Real-time monitoring and data collection: The gas analyzer can monitor the gas composition, especially the concentration of HCl gas, at the emission outlet of the cement plant in real time. By collecting and transmitting data in time, the plant can understand the emission situation and adjust the production process in time to keep the emission .

astm d695 tensile test machine

computerized tensile testing machine tension

The total system was controlled by the programmable logic controller (PLC, smart 200, Siemens, Germany), and the designed parameters for the pilot plant were shown in Table 1.As the TSP content is quite high for cement flue gas, the acoustic soot blowers were equipped for the ash sweeping over the catalyst, and the blowing interval was set at 1 h each time.

Gas analysis in cement industry Continuous monitoring to

Analyzer systems for emission monitoring, cement

Skokka é o seu portal de confiança para encontrar as melhores acompanhantes em Fortaleza. Seja você atraído por mulheres altas, peitudas, baixinhas, panicats, saradas, .

gas analyzer in cement plant|The Key Role and Application of Gas Analyzers in Cement Industr